Parallel Shaft Keys

Notes & Use

Calculates for the selection and design of parallel keys in shafts. Only compressive and shear stresses are taken into account. This calculator does not take into consideration:

- tolerances related to proper fits in a keyway

- localized stresses

- strength of the shaft and/or hub relative to the key material

- abrasion and fatigue resistance

- stresses caused by key rolling or cyclic impact loads

All key depths are assumed to be (0.5 * key height).

The calculator selects a standard key size (height × width) based on the key shape selected, and the shaft size. Note these key sizes per shaft diameter are per ANSI B17.1-1967 (R2003)

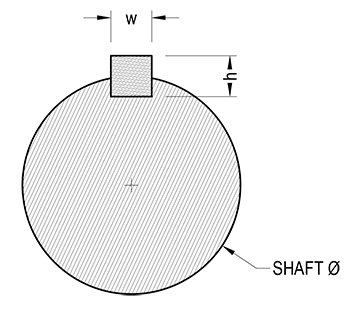

Figure

Terms

$d$ = Shaft diameter, inches

$h$ = key height, inches

$w$ = key width, inches

$l$ = key length, inches

$S$ = Safety factor, unitless

$F_{y}$ = Material yield strength, psi

$T$ = torque thru shaft, in ˙ lbf

$A_{s}$ = Shear area, square inches

$A_{c}$ = Compression area, square inches

$\sigma_{s}$ = Actual shear stress, psi

$\sigma_{c}$ = Actual compression stress, psi

$\tau_{s}$ = Allowable shear stress, psi

$\tau_{c}$ = Actual compression stress, psi

Equations

Shear area: $$ A_{s} = w \times l $$

Compression area: $$ A_{c} = \frac {h \times l} {2} $$

Actual shear stress: $$ \sigma_{s} = \frac {2 T}{d \, l \, w} $$

Actual compressions stress: $$ \sigma_{c} = \frac {4 T}{d \, l \, h} $$

Allowable shear stress: $$ \tau_{s} = \frac {0.5 F_{y}}{S} $$

Allowable compression stress: $$ \tau_{c} = \frac {F_{y}}{S} $$

Pass/Fail Test

$\sigma_{s}$ and $\sigma_{c}$ are compared to the respective allowable values:

- Pass = actual < allowable

- Fail = actual ≥ allowable

Material Yeild Strengths

The design values provided by the drop-down material box are culled from various sources. A full table of those values is as follows:

| Material | $F_{y}$ |

|---|---|

| psi | |

| C1018 Steel | 53,000 |

| C1020 Steel | 51,000 |

| C1045 Steel | 71,000 |

| C1090 Spring Steel | 78,300 |

| A36 Steel | 36,000 |

| 316 SS | 30,000 |

Sources

-

Oberg, Erik, et al., The Machinery’s Handbook, 28th ed., Industrial Press, 2008, pp. 2385.

-

Mott, Robert L. Machine Elements in Mechanical Design, 4th ed., Prentice Hall, 2003, pp. 498-500.